Find Cnc Complex Aluminum Parts, 5 Axis Aluminium, Custom CNC Parts on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Payment Type: | T/T,Paypal,Western Union |

|---|---|

| Incoterm: | FOB,CIF,EXW |

| Min. Order: | 1 Piece/Pieces |

| Delivery Time: | 15 Days |

Model No.: YP-MFG003

Custom Machining 5 Axis Aluminium CNC Milling Parts

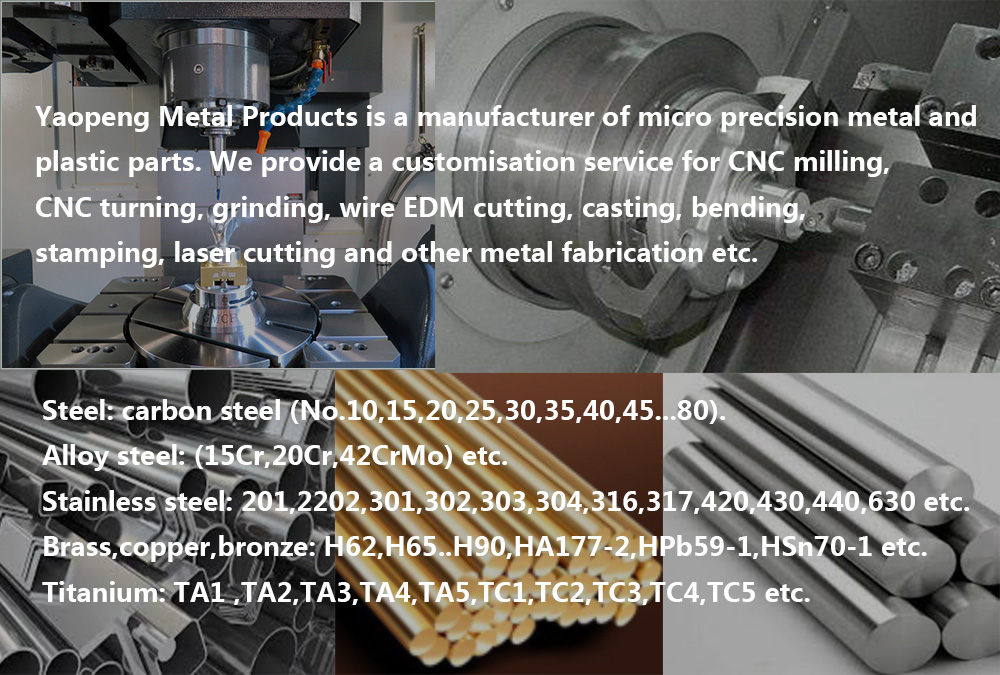

The machine tool used for five-axis machining is usually called a five-axis machine tool or a five-axis machining center. Five-axis machining is commonly used in the aerospace field to process body parts, turbine parts and impellers with freeform surfaces. The five-axis machine tool can process different sides of the workpiece without changing the position of the workpiece on the machine tool, which can greatly improve the processing efficiency of the prismatic parts.

We are a custom factory,Main business scope is CNC Turning Machining, CNC Milling Machining, CNC Machining Parts, Plastic Parts,Sheet Metal, Die Casting and so on. If you are interested in our 5 Axis CNC Machining Parts , please feel free to contact me. Any enquiries that you make will get a prompt response. Products Information: Material: Aluminum/ stainless steel Surface treatment: Polishing Production processing: 5 Axis CNC Machining Parts Product usage: mold and some other industries Tolerance: +-0.01mm Products images:

If you are interested in any of our products, contact us to talk about the details:

Product Categories : CNC Machining Parts > 5 Axis CNC Machining Parts